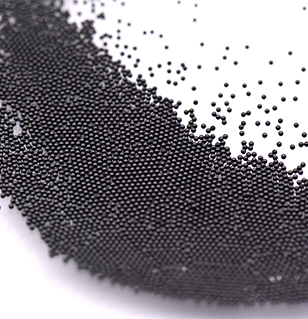

GPS Silicon Nitride (Si3N4) Ball

Silicon nitride is a hard ceramic having high strength over a broad temperature range, moderatethermal conductivity, low coefficient of thermal expansion,moderately high elastic modulus, and unusually high fracture toughness for a ceramic. This combination of properties leads to excellentthermal shock resistance, ability to withstand high structural loads to high temperature, and superior wear resistance.

Name | Size | Grade | Sintering Technology |

Sinoma Si3N4 Ball | φ 1mm-50.8mm | 5-100 | GPS |

Application: machine tool spindles, dental drills, electric motors, bicycles, ball screws, pumps

Gas pressure sintering (GPS) process is one of the most promising sintering techniques for the fabrication of high performance silicon nitride ceramics. Almost pore-free densified compacts with low amounts of sintering additives can be obtained by this process. They present high strength with high reliability and good heat resistance. These properties make them one of the best candidate materials for heat engine component as well as other industrial fields application. The gas pressure sintered silicon nitride (GPSSN) ceramics densified to high density have already been applied in turbocharger rotors for automotive application, cutting tools and bearing balls for industrial applications, etc., and have been highly evaluated for high strength and reliability.

The special feature of the GPS process is a sequence of dewaxing at low pressure, sintering at normal pressure and -after a status is reached with only closed pores being present in the material - sintering at a high pressure, which results in a further densification and faster elimination of the remaining pores. Therefore materials produced in the GPS technology show in general mechanical properties (hardness, strength, Weibull-modulus, fracture toughness) which are superior to those of pore-free materials produced by the conventional sintering method.

The devices are particularly suitable for sintering such types of ceramics or metals, which tend to decomposition at elevated temperatures or which do not sinter to high densities in standard sintering operations. This process has not the limitations with respect to the shape of the manufactured parts as in hot pressing and it is also an advantageous alternative to the more costly HIP-process.